About The Company

Our operations span across Asia, where we house our cutting-edge manufacturing facilities. Our products have gained global recognition, finding applications in various industries, with a notable presence in the automotive glass processing sector. We are esteemed as one of the primary suppliers for automotive glass grinding and processing needs, both within Asia and on a global scale.

Our grinding wheels and drilling tools, designed specifically for automotive glass applications, have found widespread use in collaborations with industry giants such as Saint-Gobain, AGC, NSG, and Fuyao Group, among others. This speaks to the high quality and reliability of our products, which are trusted by key players in the automotive glass sector.

TORNADOGRIND has strategically positioned itself to cater to the European Market, offering top-notch quality and superior services to automotive glass manufacturers. We are committed to delivering excellence and meeting the specific demands of this market, further solidifying our reputation as a trusted partner in the industry

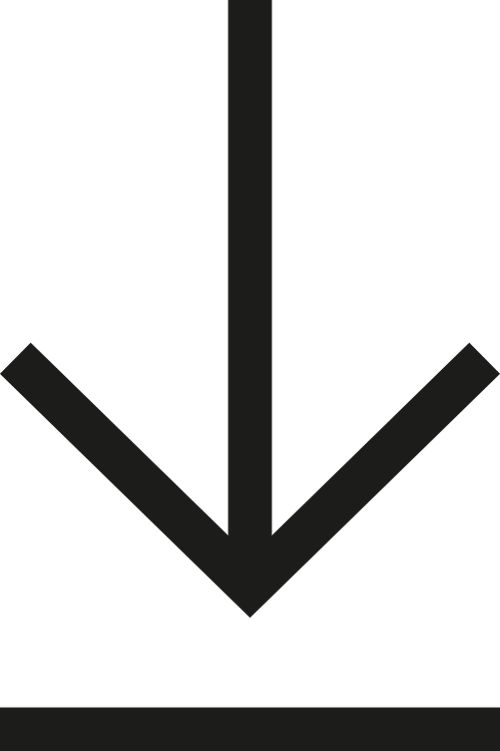

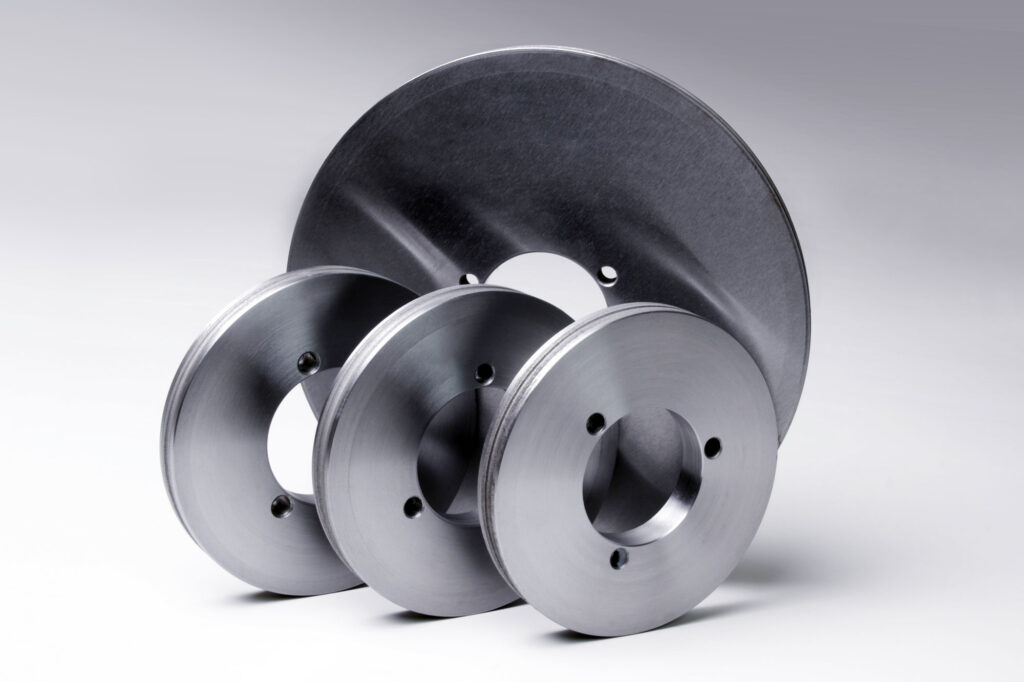

TORNADO-2301 is newly designed high precision product from TORNADOGRIND dedicated to pencil edging for automotive glasses on Bystronic CNC machines.

The TORNADO-2301 is designed to enable quick start-up, endurable operational life, high precision in processing quality and lower lifetime cost.

TORNADO-2301 with our unique diamond coating according to grinding conditions and workpiece materials ensure high adaptability and chip-free grinding, as well as a longer wheel life between re-profiling.

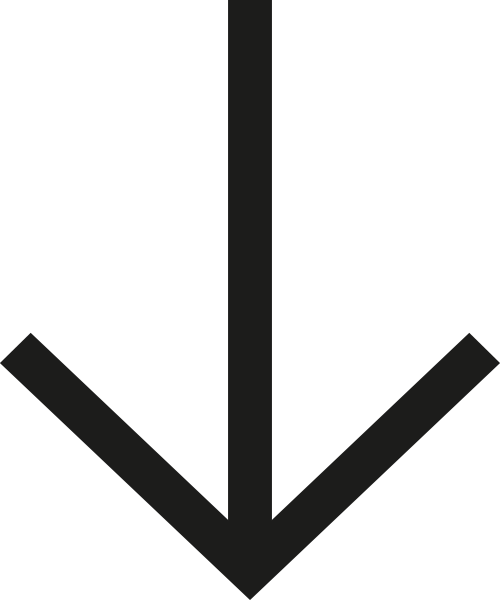

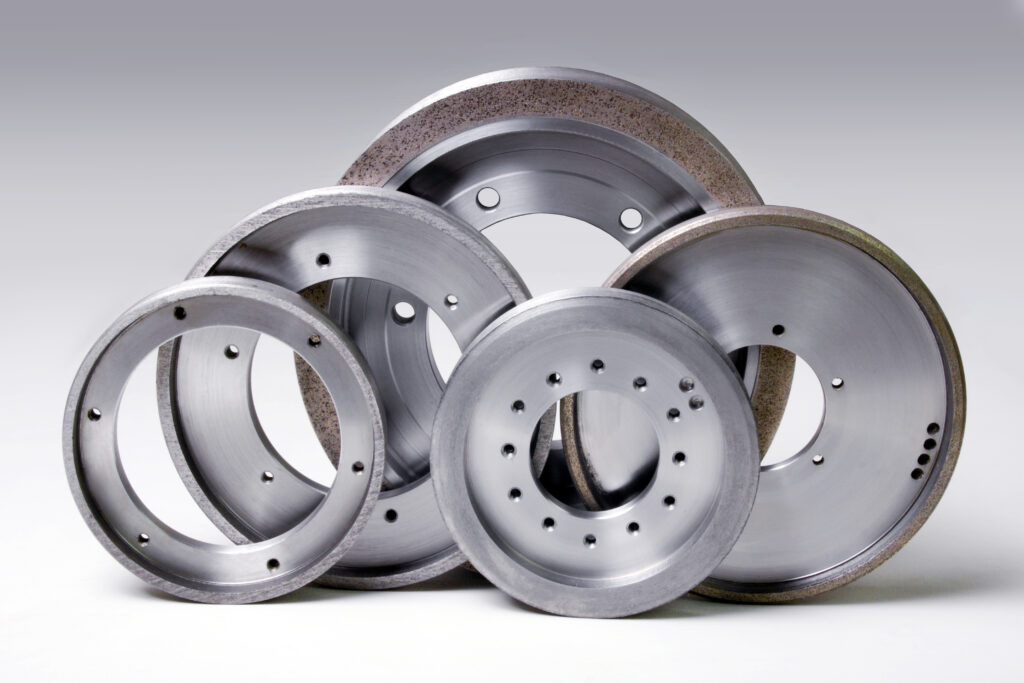

TORNADOGRIND wheels are designed to fit in all leading CNC machines, the dimensions and size of the grinding wheel are precisely controlled to ensure a stable grinding process and consistent product quality based on specific grinding CNC machines and customer requirement.

TORNADOGRIND also provide high quality re-profiling services of the grinding wheels which will reduce the overall life cost for customers by using EDM systems.

TORNADO-2302 is newly designed high precision product from TORNADOGRIND dedicated to pencil edging for automotive glasses on Bando CNC machines.

The TORNADO-2302 is designed to enable quick start-up, endurable operational life, high precision in processing quality and lower lifetime cost.

TORNADO-2302 with our unique diamond coating according to grinding conditions and workpiece materials ensure high adaptability and chip-free grinding, as well as a longer wheel life between re-profiling.

TORNADOGRIND wheels are designed to fit in all leading CNC machines, the dimensions and size of the grinding wheel are precisely controlled to ensure a stable grinding process and consistent product quality based on specific grinding CNC machines and customer requirement.

TORNADOGRIND also provide high quality re-profiling services of the grinding wheels which will reduce the overall life cost for customers by using EDM systems.

Bystronic core drill / core dill seamers are specialized tools primarily designed for the core drilling and chamfering of holes in automotive glass on Bystronic CNC machines. Our product line includes a wide selection of drills, encompassing one-piece straight core drills and dual-piece drill designs, tailored to meet the exact specifications of the automotive industry.

The lifespan of a core drill is contingent on the number of holes it can successfully create. Typically, a core drill can undergo redressing multiple times. The redressing process involves precision adjustments to the drill‘s depth, using a silicon carbide (SIC) wheel, until the wall thickness returns to standard levels. TORNADO drill bits, when utilized on automotive glass, consistently achieve impressive results, often exceeding 10,000 holes.

The quality of a core drill bit is also assessed by the quantity of chips produced on the glass surface, which is typically evaluated through visual inspection. This stringent quality control ensures that the final product meets the demanding requirements of the automotive industry.